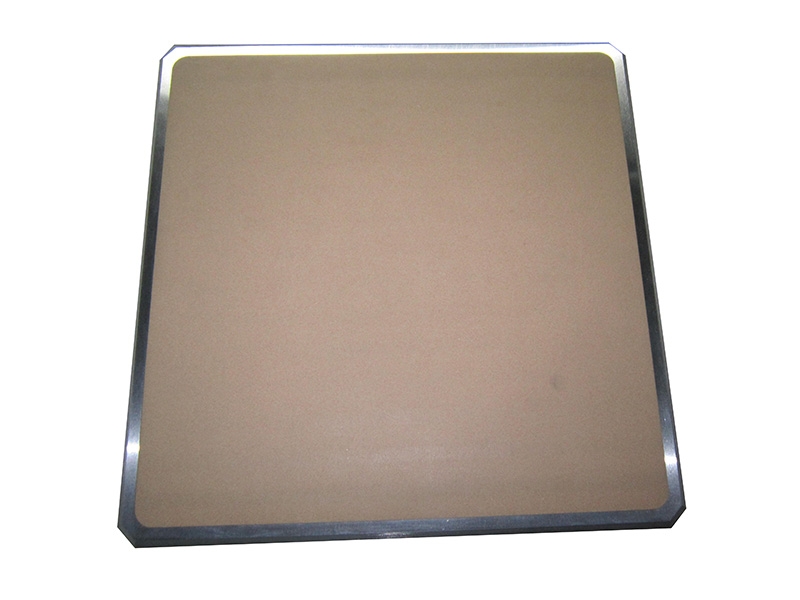

Ceramic vacuum suction cup application:

Widely used in semiconductors, laser cutting, PCB, flexible screens, film adsorption, robotic arm transportation, semiconductor product detection, magnetic materials, vacuum suction cups in the electronics industry, etc.

1. The pore rate is 40-50%ceramic, precision wear -resistant.

2. The pores are small (10-30um), and the adsorption is stable.

3. Ads to multiple objects at the same time.

4. High level of plane, fit with the product.

5. The adsorption force is designed according to the adsorption product.

6, smooth surface (RA1.4-2.0), there is no risk of leaving adsorption marks on the thin object

7. Multiple objects at the same time.

Factors affecting vacuum suction cups

1. The quality of the transferring object -determines the size and quantity of the suction cup.

2. The shape and surface state of the transmitted object -Select the type of suction cup.

3. Working environment (temperature) -choose the material of the suction cup.

4. Connection method -suction cups, connectors, buffer connectors, robotics.

5. The height of the transferring object.

6. Cushioning distance.

.png)