Common Scraper Applications and Defect Analysis

Time:2025-11-12

Views:2

Common Scraper Applications and Defect Analysis

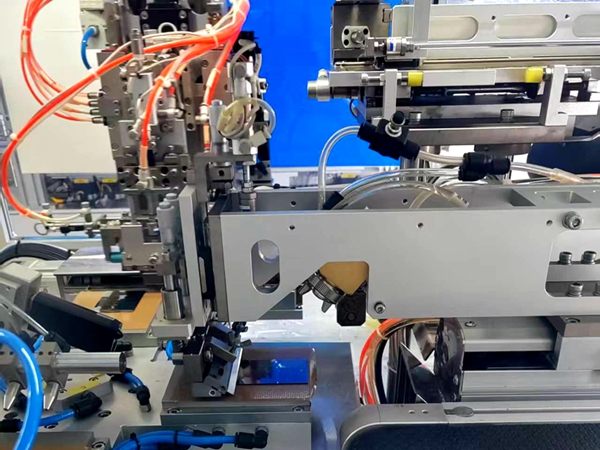

Precision scrapers include dust removal scrapers, screen scrapers, glass scrapers, powder scrapers, and roller scrapers.

The function of a scraper is to remove unwanted materials or materials that need to be separated from the workpiece from the working surface. The common working method is a reciprocating motion of the scraper, although there are also cases where the scraper is stationary while the workpiece moves; in short, relative motion is required to complete the scraping process.

For example, screen scrapers and glass scrapers are widely used in industrial applications. With the popularization of electronic products, the application of display screens has increased, such as mobile phone screens, computer screens, and LED display screens in various home appliances. During the screen cutting and packaging process, surface dust removal is required, and the most direct method is to use a scraper to remove dust and particulate matter from the screen surface.

Users often complain about poor scraping performance of their scrapers. Common reasons for this include:

1. Poor scraping effect after installation;

2. Inconsistent performance with scrapers from the same batch;

3. Short scraper lifespan and poor wear resistance;

4. Scrapers that worked well for friends resulted in higher screen or glass surface defects for users.

During follow-up surveys of customers, Deren Precision Engineering summarized the following reasons and ultimately resolved them for customers:

1. For poor scraping performance after installation, rule out installation issues and ensure the scraper holder is flat, smooth, and free of foreign objects. Also, check the scraper blade edge for nicks or chips; the most common method is to observe the straightness and size of the nick under a microscope. If the problem is with the blade edge, replace the blade; if the problem is with the scraper holder, finely grind the holder to ensure flatness.

2. Inconsistent performance is a common problem encountered by most users. If the product and tool holder remain unchanged, the scrapers need to be categorized. High-quality blades should be separated from blades prone to chipping, and difficult-to-machine materials should be separated from easy-to-scrape materials. Corresponding custom scrapers should be used for targeted solutions to avoid using a single blade for everything.

3. If the product is produced stably and continuously, more wear-resistant blades should be replaced with custom-made blades with longer lifespans. Compare usage under identical conditions; investing more in high-quality scrapers will save time, improve efficiency, and reduce overall costs, making it more cost-effective!

4. The suitability of scrapers varies depending on the precision of the application equipment. For example, DRMFG scrapers are available in 88x18x0.25mm and 88x18x0.5mm sizes. Some customers find the 0.5mm blade performs better, while others find the 0.25mm blade performs better. Through comparative analysis, scrapers of the same material and precision, differing only in thickness, can have significantly different performance results. For precision equipment, 0.25mm inserts provide a more secure clamping grip and better performance; ordinary equipment can only use 0.5mm inserts, as 0.25mm inserts are not clamped tightly enough, resulting in a high defect rate. Therefore, it is necessary to select the appropriate insert based on the equipment. Furthermore, for customers whose equipment cannot use 0.25mm inserts, our company can modify the tool holder and fixtures, and the performance of using 0.25mm inserts immediately improves significantly. This is a modification service I provided to customers during the manufacturing of precision scrapers, and it‘s also a sharing of experience in resolving performance issues.

Welcome to contact me for further discussion: [email protected]

.png)